Edge banding

Edge banding-the perfect partner of the board, not only makes the furniture look more beautiful and feels smoother, but also can effectively control the amount of formaldehyde released in the cotton board, making our wardrobes and cabinets more green and environmentally friendly.

Description

Decorative Edge band

Edge banding or edgebanding is the name of both a process and an associated narrow strip of material used to create durable and aesthetically pleasing trim edges during finish carpentry.

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. Common substitutes for edge banding include face frames or molding. Edge banding can be made of different materials including PVC, ABS, acrylic, melamine, wood or wood veneer.

Traditional edge banding was a manual process requiring ordinary carpentry tools and materials. In modern applications, particularly for high-volume, repetitive manufacturing steps such as cabinet doors, edge banding is applied to the substrate by an automated process using a hot-melt adhesive. Hot melt adhesives may consist of various raw materials including EVA, PUR, PA, APOA, and PO.

A substrate primer may also be used as a bonding agent between the adhesive and the substrate. Thicker edge bandings typically require a slight concavity to provide a tight glue line. The thickness can vary from .018″ to 5mm or even more. The machine that applies the edge banding is called edge bander. An edge bander bonds the edge banding to the substrate, trims the leading and trailing edges, trims top and bottom flush with the substrate, scraps any surplus, and buffs the finished edge.

Edge banding is a thin material used to seal the exposed and raw edges of plywood. Heat sensitive adhesive on one side is applied to the board while the other side acts as a barrier against dirt and moisture. Edgebanding is mainly done to cover plywood sides in order to match a cabinet’s finished look, but it also protects the inner plywood from possibly warping. Edge Banding is available in variety of materials, but there are two categories that are most commonly used : PVC and Veneer.

Plywood, particle board, and other manufactured wood cores like MDF have rough, unfinished, unprotected, and generally unsightly edges.

To account for that, some clever folks developed technologies that allow you to glue different bands of glossy finished material to those rough edges to match the tops and sides.

Those narrow bands or strips are called edging tape, and they range in thickness from 0.018-inch to 5mm thick and come in 250 ft rolls.

The thicker edging is used in high traffic and commercial environments because it provides greater resilience and impact resistance. For example, the military requires a thicker ⅜” solid wood edge banding for maximum impact resistance.

And edge banders are the industrial grade machines that apply the edging tape to the raw edges of the wood panels with a hot-melt adhesive or glue.

Features

- Professional Finish

- Edge band tape provides a seamless and polished appearance, giving your furniture a professional finish that is aesthetically pleasing.

- Durability

- Edge band tape is highly durable and resistant to wear and tear, making it an ideal choice for high-traffic areas such as kitchens and bathrooms.

- Cost-effective

- Compared to other finishing methods, edge band tape is a cost-effective solution that can help you achieve professional results without breaking the bank.

- Versatility

- Edge band tape comes in a variety of colors, patterns, and widths to suit different types of furniture and design preferences, allowing you to customize your project as desired

- Easy to Use

- Edge band tape is easy to apply with an iron or edge banding machine, making it a convenient solution for both DIY enthusiasts and professionals.

Application

Applied for Kitchen decorative edge banding, Office furniture edge banding, Board type furniture edge banding, also applies to mdf board,plywood,WPC board, kitchen cabinet, and other construction decorations.

Specification

Specification

| Material: | PVC,ABS,Acrylic,environmentally friendly materials according to your requirement | |||

| Thickness: | Thicness:0.4mm – 5mm, Or customized | |||

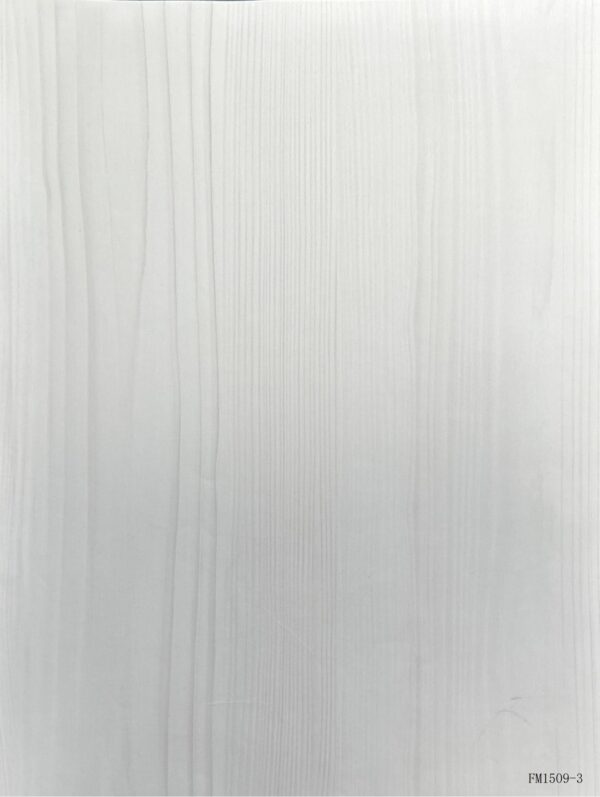

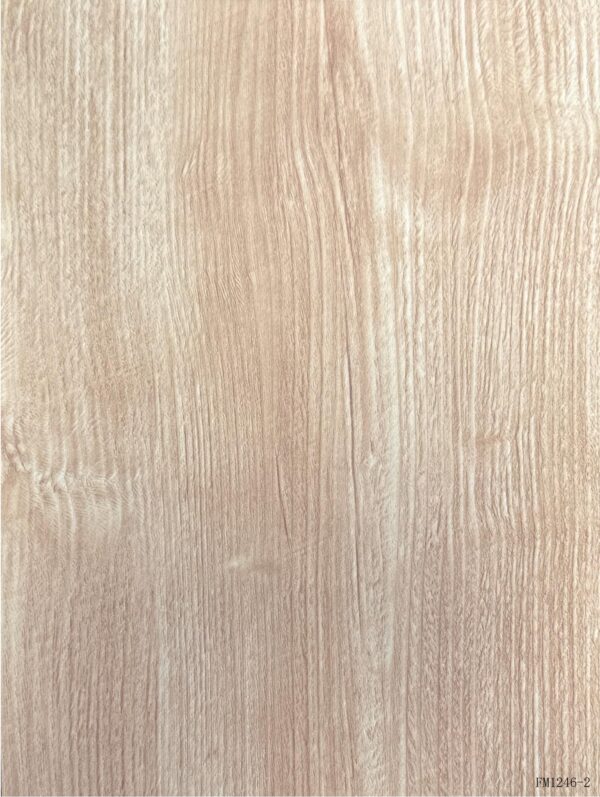

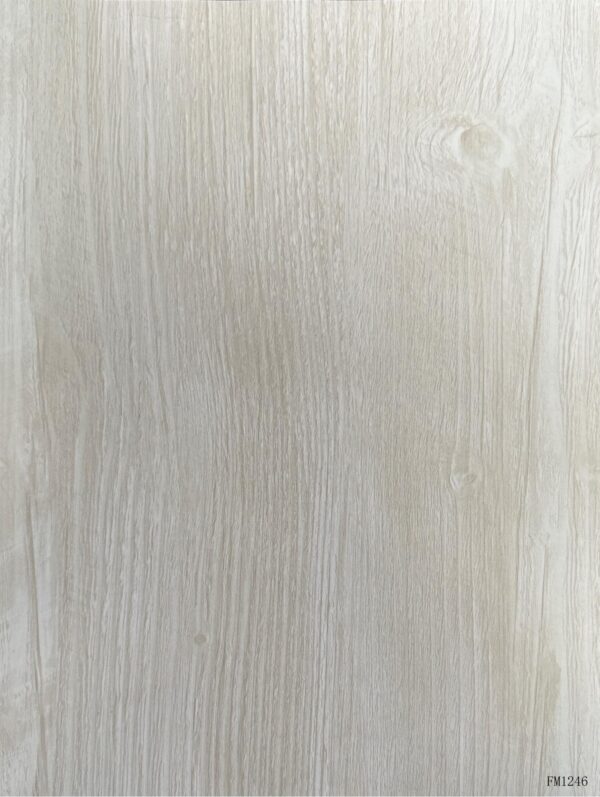

| Color: | Wood Grain, Solid Color, Shine, Glossy, etc | |||

| Finish: | High Glossy, Matt, Super Matt, Textured | |||

| Packing: | 100m/roll, 200m/roll, rolls in carton, or as your requirements. Customized design, logo, words can be on cartons, labels . | |||

| MOQ: | 2000m | |||

| Features: | Non-color variation after trimming ; | |||

| Superior durability/wearability;Excellent light stability,Strong bondings strength | ||||

| Stain and chemical resistance; | ||||

| No pressure whitening;Phthalates free | ||||

Product show

Contact us

Get free sample

To contact us please use the following form to submit your enquiry, We will contact you as soon as possible.

Other Products

-

Wood Grain interior design melamine coated wood decorate surface paper | FM-3050

-

Wood Grain interior design melamine board 4 x 8 decorate surface paper | FM-3049

-

Wood Grain kitchen cabinet melamine board decorate surface paper | FM-3048

-

Wood Grain design melamine plates decorate surface paper interior design | FM-3047